High standard factory

about KSM Machinery

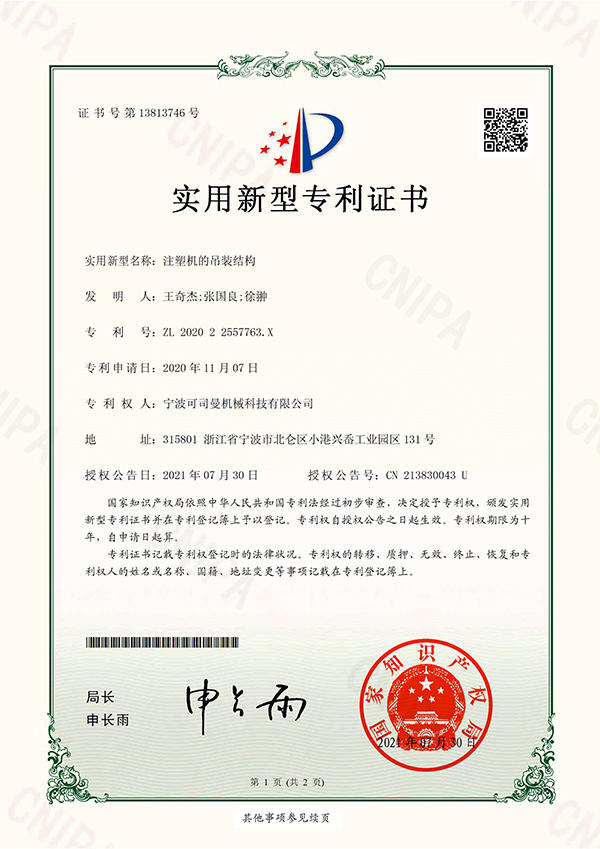

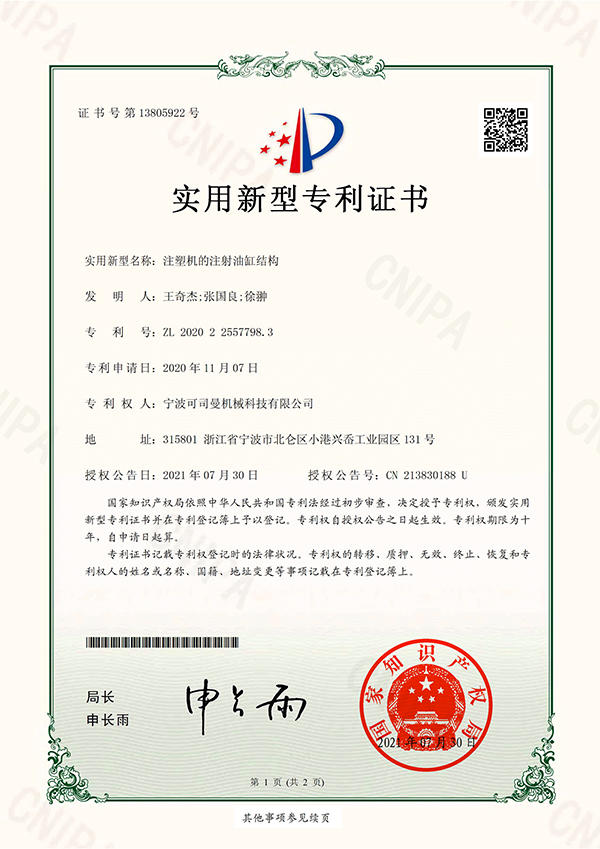

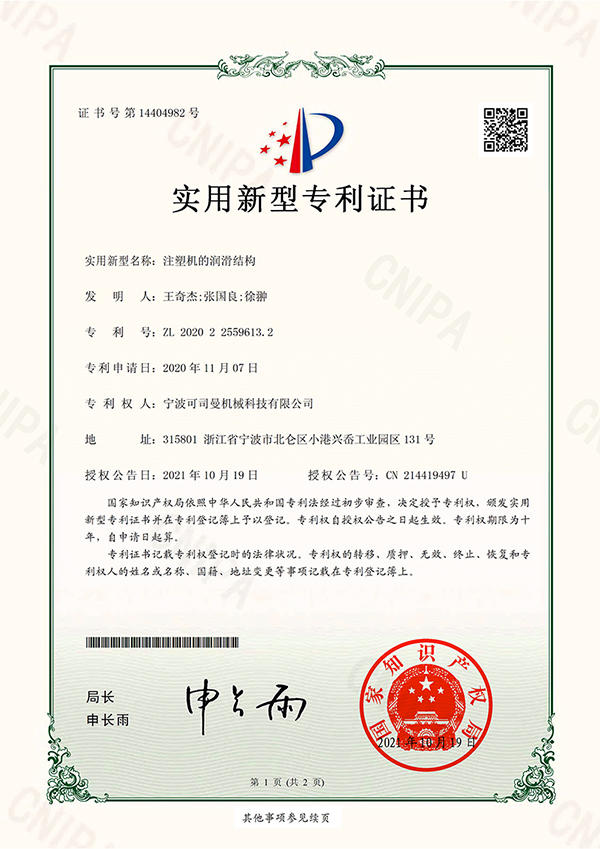

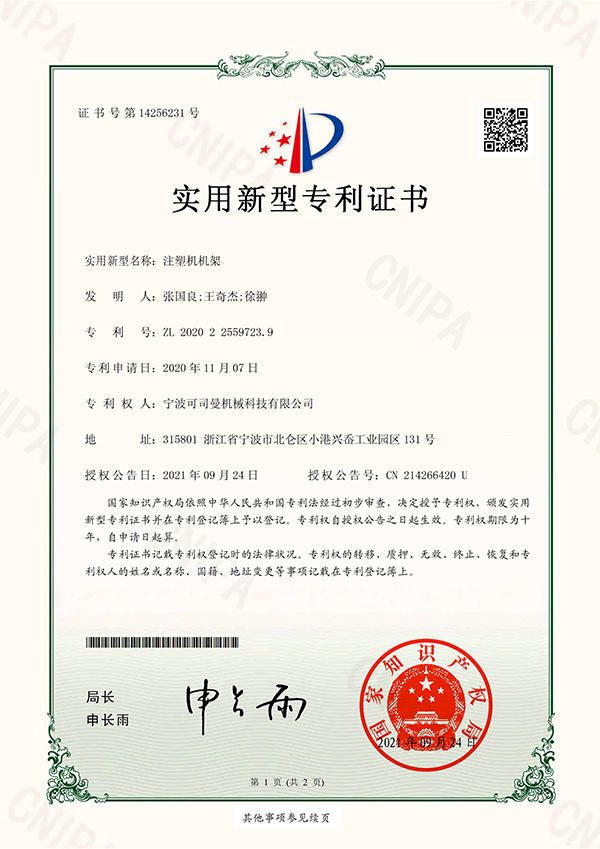

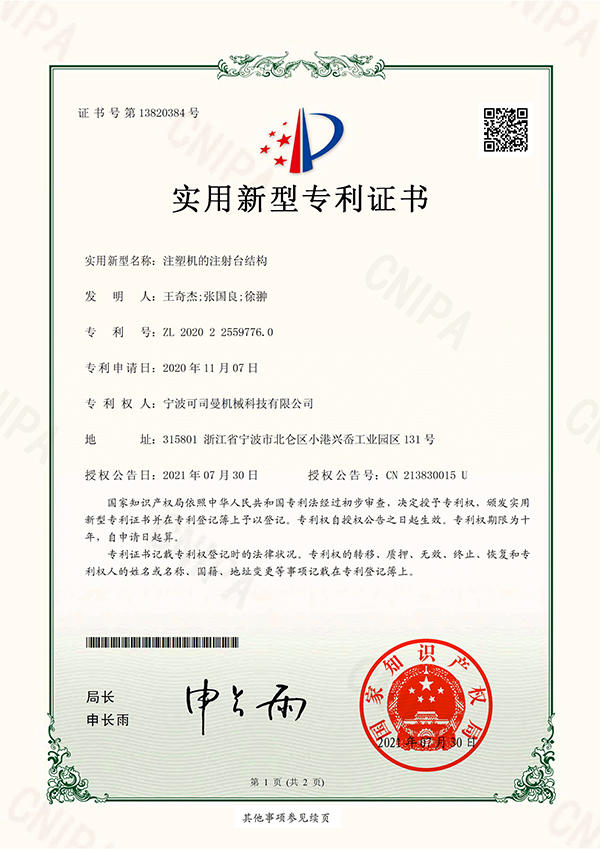

Ningbo KSM Machinery Manufacturing Co.,Ltd. is a cooperate with Italy technologies specialized high-grade plastic in production of high-grade plastic molding machine. Our corporation is located in Ningbo Beilun Xing Ao Industrial Park. We have a number of R&D personnel and cooperate with a group of high-tech enterprise.

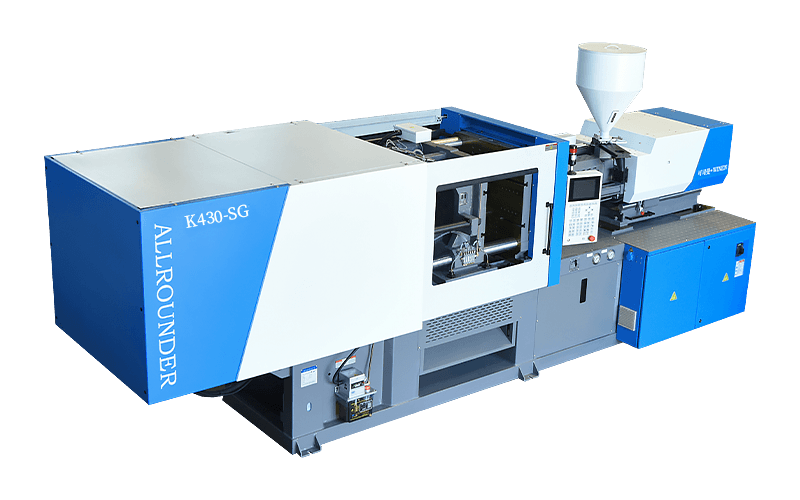

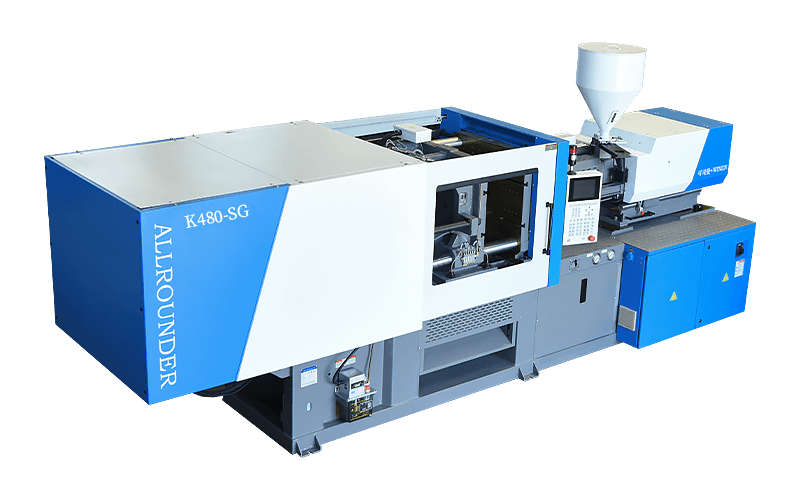

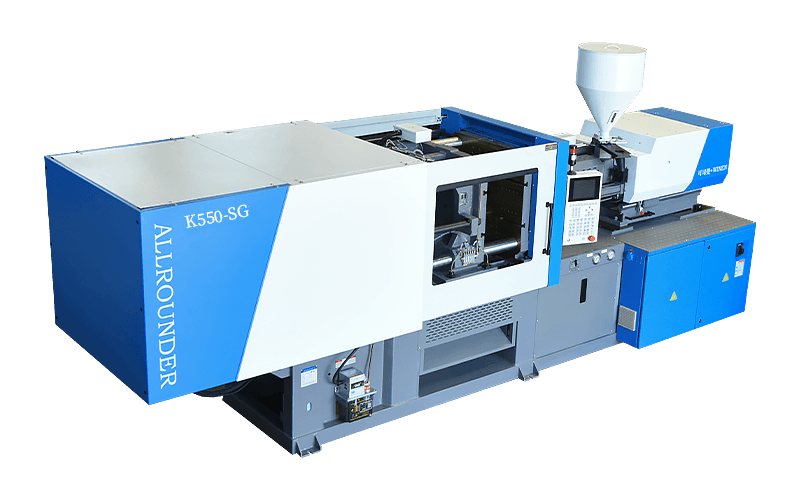

As a professional China KSM Plastic Injection Molding Machine Fruit Basket Machine manufacturers and KSM Plastic Injection Molding Machine Fruit Basket Machine factory, it mainly produces high precision injection molding machines with the clamping force range from 110T to 1850T. The products have high rigidity structure and equipped imported hydraulic & electrical elements, used screw with mixing head in order to have excellent plastifying performance and be suitable for various engineering plastic injection molding and the uers'special order are available.

Since its corperation established, has always paid attention to enterprise reputation,carrid out scientific, management with rational designs, rests with quality pre-sale, selling and after-sale services to win the vast number user's trust and approval.

We abide by the motto of "honest, keep on improving, lay stress on quality, never relax in effort". Sincerely welcome friends from all wask for guidance.

The company has a research and development center with strong development strength. At the same time, it cooperates with domestic universities and colleges to develop and research injection and plastic production equipment and injection molding machine. The company has advanced hose testing equipment and experimental equipment. In recent years, the R&D center has achieved many achievements in injection molding machine and plastic equipment, rubber vulcanization process and formulation development.

Sincerely invite customers at home and abroad to visit our factory, and look forward to your long-term corporation to create a beautiful tomorrow for you!

English

English 中文简体

中文简体

.png?imageView2/2/format/jp2)