The plastic injection fruit basket machine is a marvel of modern technology that allows for the efficient and precise manufacturing of fruit baskets. This machine operates based on a few fundamental principles.

The first step in the process is mold preparation. The mold plays a crucial role in shaping and forming the plastic material into the desired fruit basket design. Therefore, it is essential to ensure that the mold is clean and free from any residue or debris that may affect the quality of the final product. Lubrication is also applied to the mold to facilitate the easy release of the solidified plastic.

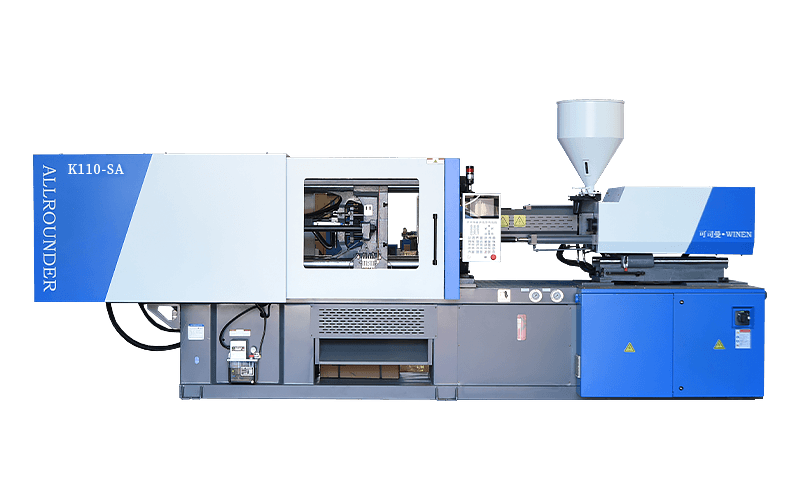

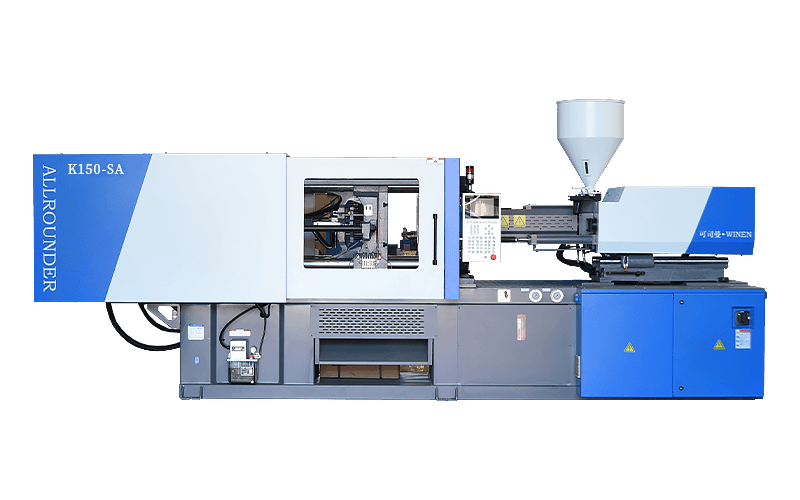

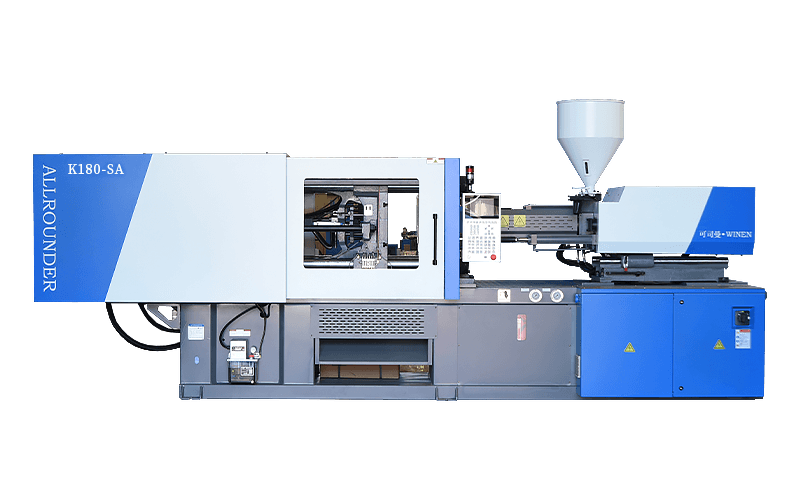

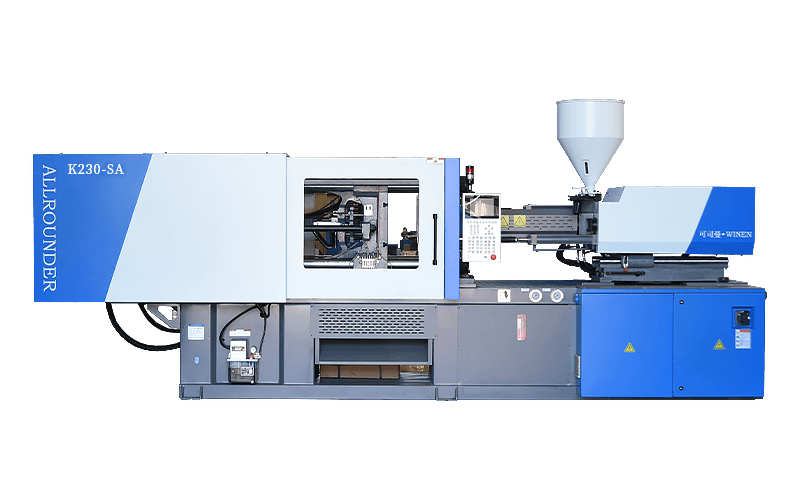

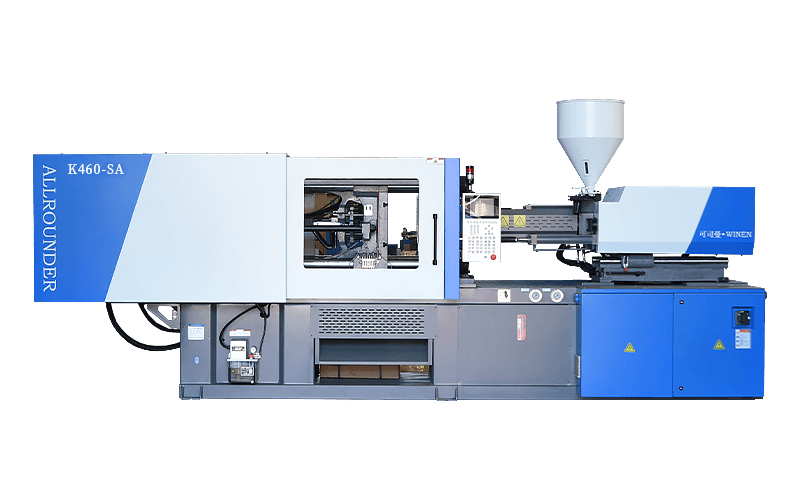

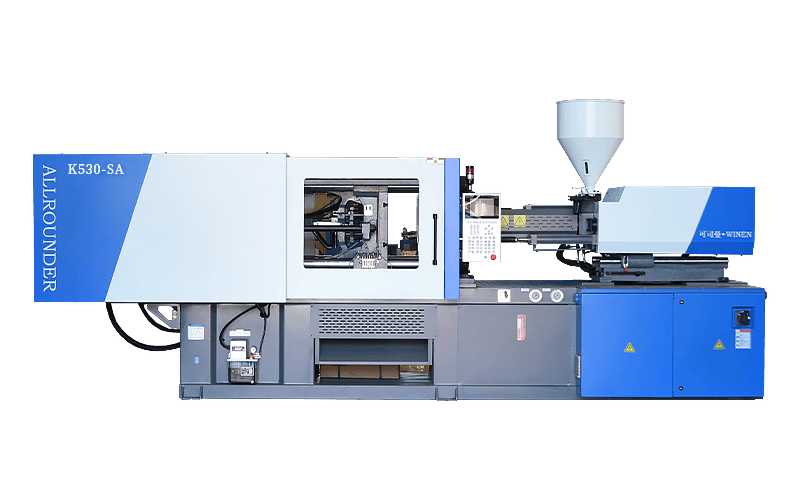

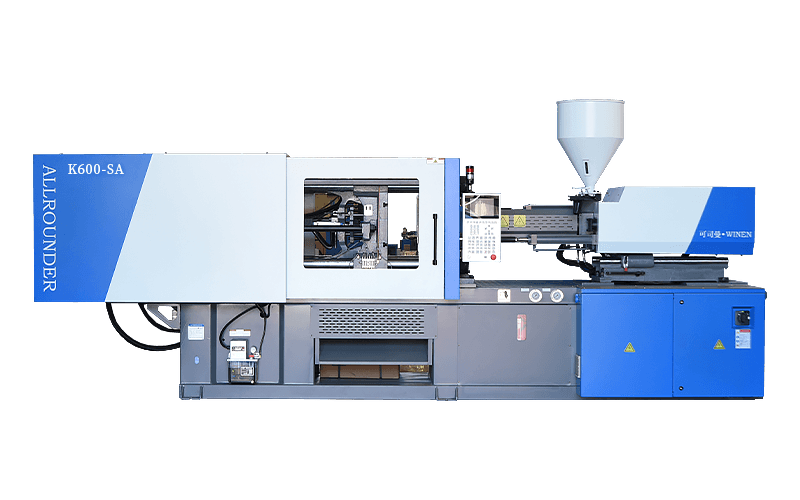

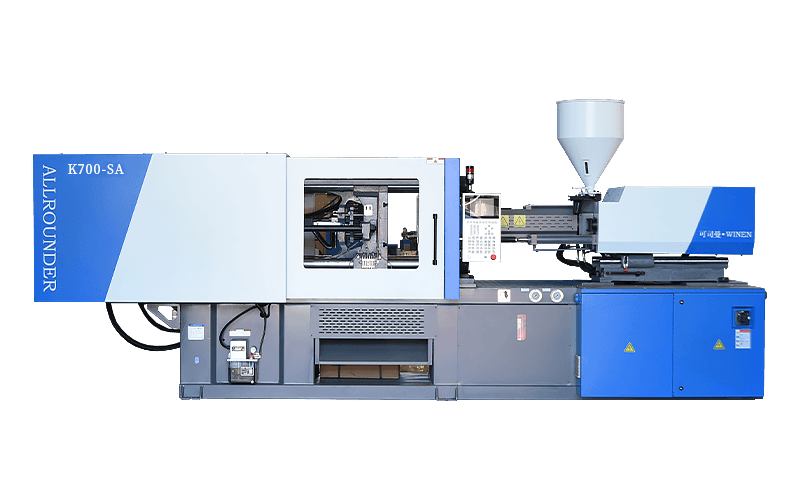

The next step involves heating and melting plastic pellets or resin. These pellets, made from various types of plastic, are fed into the machine's hopper. The machine has a heating element that liquefies the plastic material, typically through the use of high temperatures and pressure. Once the plastic is fully melted, it becomes viscous and ready for injection.

Injection is the key process in which the liquid plastic is forced into the mold cavity. The machine utilizes a reciprocating screw or a plunger to push the molten plastic into the mold under high pressure. This pressure ensures that the plastic evenly fills the mold and takes on the desired shape. The mold consists of two halves, known as the core and cavity, which join together to form the complete shape of the fruit basket.

After the plastic is injected into the mold, the machine cools it down rapidly. Cooling is facilitated through the circulation of water or a cooling agent within the mold. The quick cooling process helps solidify the plastic and sets it into the desired shape. Once the plastic has solidified, the mold is opened, and the newly formed fruit basket is ejected from the machine.

It is worth noting that the plastic injection fruit basket machine operates with a high degree of automation and precision. Computer numerical control (CNC) technology is often employed to programmatically control the machine's movements, ensuring accuracy and consistency in every production cycle. The machine can be programmed to regulate temperature, pressure, and other critical parameters, guaranteeing the production of high-quality fruit baskets.

English

English 中文简体

中文简体